Conduit fittings play a crucial role in electrical systems, ensuring the safe and efficient transmission of electrical currents. Regular inspection and maintenance of these fittings are essential to prevent malfunctions and ensure the longevity of the electrical system. In this article, we will discuss the importance of conduit fittings, the basics of inspection, steps to maintain them properly, troubleshooting common issues, and ensuring compliance with electrical codes.

Understanding the Importance of Conduit Fittings

Conduit fittings serve as the connection points between sections of electrical conduit, protecting the enclosed wiring and facilitating the passage of electrical conductors. They provide a secure and insulated pathway for the wires, protecting them from physical damage, moisture, and other environmental factors. Without proper conduit fittings, electrical installations would be vulnerable to accidents, malfunctions, and even fires.

When it comes to electrical systems, safety is of utmost importance. Conduit fittings play a crucial role in ensuring the overall safety and functionality of the system. They not only protect the wires from external elements but also help in organizing and managing the electrical wiring. Click here for a comprehensive overview of sustainable electrical supplies.

But what exactly is the role of conduit fittings in electrical systems? Let’s delve deeper into their significance.

Role of Conduit Fittings in Electrical Systems

Conduit fittings serve as the vital link between the various components of an electrical system. They provide a secure and reliable connection between conduits, junction boxes, and electrical devices. This connection ensures the uninterrupted flow of electric current, allowing for efficient power distribution and reducing the risk of electrical hazards.

Imagine an electrical system without conduit fittings. The wiring would be exposed, susceptible to damage from external factors such as moisture, dust, and physical impact. This could lead to short circuits, electrical shocks, or even fires. Conduit fittings act as a protective shield, safeguarding the wiring and preventing any potential hazards.

Additionally, conduit fittings help in organizing and routing the electrical wiring. They allow for neat and orderly installations, making it easier to identify and troubleshoot any issues that may arise. This not only saves time but also minimizes the chances of accidental damage during maintenance or repairs.

Furthermore, conduit fittings provide flexibility in electrical system design. They allow for easy modifications and expansions, as new conduits can be added or existing ones can be extended using appropriate fittings. This adaptability is particularly beneficial in commercial and industrial settings where electrical systems may need to be reconfigured or upgraded to accommodate changing needs.

Why Regular Inspection and Maintenance is Crucial

To ensure the integrity of your electrical system, it is essential to conduct regular inspections and maintenance of the conduit fittings. Over time, fittings can deteriorate due to wear and tear, environmental factors, or improper installation. Regular inspections can identify any potential issues and allow for timely repairs or replacements, preventing costly damages and ensuring the system’s optimal performance.

During inspections, it is important to check for signs of corrosion, loose connections, or physical damage to the fittings. Corrosion can weaken the fittings, compromising their ability to protect the wiring. Loose connections can lead to electrical arcing, which can cause overheating and damage to the surrounding components. Physical damage, such as cracks or breaks in the fittings, can expose the wiring to external elements, increasing the risk of electrical hazards.

In addition to inspections, regular maintenance should include cleaning the fittings to remove any dirt, dust, or debris that may have accumulated over time. This helps maintain the efficiency of the fittings and prolong their lifespan.

By prioritizing regular inspection and maintenance of conduit fittings, you can ensure the safety and reliability of your electrical system. It is always better to be proactive and address any potential issues before they escalate into major problems that can disrupt your daily operations or pose a threat to the occupants of a building.

So, remember, conduit fittings are not just simple connectors. They are integral components that play a vital role in protecting your electrical system and ensuring its smooth operation. Take the time to understand their importance and invest in proper maintenance to keep your electrical system running efficiently and safely.

Basics of Conduit Fittings Inspection

Before starting the inspection process, it is important to take necessary safety measures. Ensure you have the appropriate protective gear, such as gloves and safety glasses, to minimize any potential hazards. Additionally, make sure to turn off the electrical power supply and follow all standard lockout/tagout procedures.

Conduit fittings play a crucial role in electrical systems, providing a secure and reliable connection between different sections of conduit. Regular inspection of these fittings is essential to ensure the safety and efficiency of the electrical installation.

Pre-Inspection Safety Measures

Prior to inspecting conduit fittings, it is crucial to shut off the power supply and verify its absence using a voltage tester. By doing so, you eliminate the risk of electrical shocks or short circuits. Always follow the established safety protocols to minimize any potential risks associated with working on electrical systems.

Once you have taken the necessary safety precautions, you can proceed with the inspection process. Start by visually examining the conduit fittings for any visible signs of damage or deterioration. This initial assessment will help you identify areas that require closer inspection.

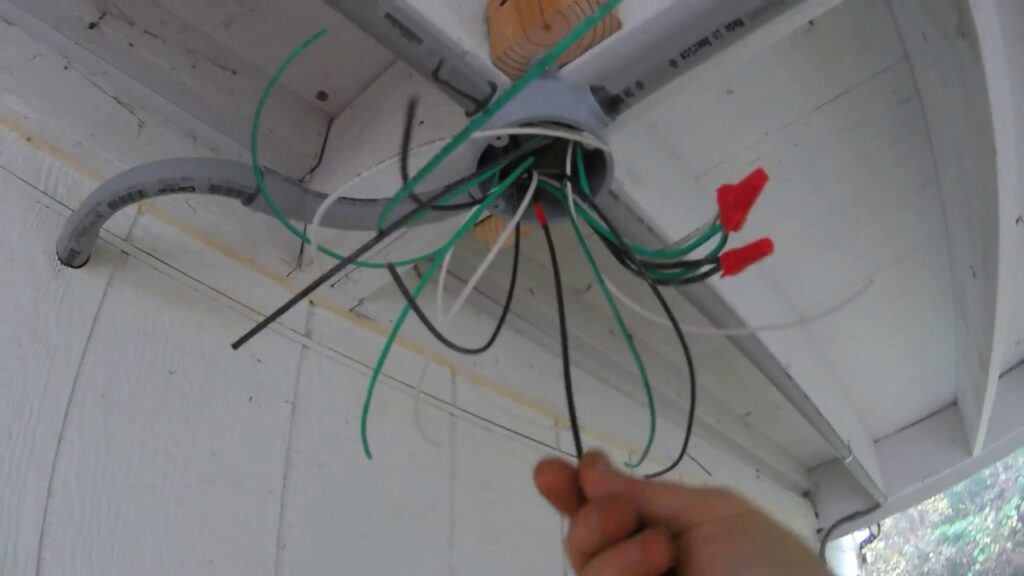

Key Inspection Points to Consider

During the inspection, pay close attention to the condition of the fittings. Look for signs of corrosion, rust, or physical damage. Corrosion can weaken the fittings and compromise their ability to provide a secure connection. Rust, on the other hand, indicates moisture infiltration, which can lead to further deterioration.

Check for loose or deteriorated connections. Over time, fittings may become loose due to vibrations or thermal expansion and contraction. Loose connections can cause electrical arcing, leading to overheating and potential fire hazards. Deteriorated connections, such as cracked or broken fittings, should be replaced immediately to maintain the integrity of the electrical system.

It is also important to inspect for any signs of overheating, such as discoloration or melting of the fittings. Overheating can be caused by excessive current flow or poor conductivity within the fittings. This can lead to insulation damage and increased risk of electrical faults.

Additionally, examine the general condition of the conduit, making sure it is securely fastened and properly aligned. Loose or misaligned conduit can put strain on the fittings, leading to premature wear and potential failure. Ensure that the conduit is adequately supported and free from any obstructions that may impede its functionality.

Regular inspection and maintenance of conduit fittings are essential to prevent electrical failures and ensure the safety of both personnel and equipment. By following the recommended inspection procedures and addressing any issues promptly, you can maintain the reliability and efficiency of your electrical system.

Steps to Properly Maintain Conduit Fittings

Maintaining conduit fittings involves a combination of regular cleaning, lubrication, and timely replacement of damaged fittings. By following these steps, you can extend the lifespan of your conduit fittings and ensure their optimal performance.

Conduit fittings are essential components in electrical systems, providing a secure and reliable connection between different sections of conduit. Proper maintenance of these fittings is crucial to ensure the safety and efficiency of the electrical installation.

Now, let’s delve deeper into the steps involved in maintaining conduit fittings:

Cleaning Conduit Fittings

Periodically cleaning conduit fittings is essential to remove any dirt, dust, or debris that may accumulate over time. This accumulation can hinder the proper functioning of the fittings and potentially lead to electrical issues.

When cleaning conduit fittings, it is recommended to use a damp cloth or brush. Gently wipe or brush away any visible dirt or debris, ensuring that you reach all the nooks and crannies of the fittings. Pay special attention to areas where the fittings connect to the conduit, as these are prone to collecting debris.

After cleaning, it is crucial to ensure that the fittings are completely dry before proceeding to the next step.

Lubricating Conduit Fittings

Once the conduit fittings are clean and dry, the next step is to apply a suitable lubricant. Lubrication plays a vital role in maintaining the performance and longevity of the fittings.

Using a lubricant specifically designed for electrical fittings, apply a thin layer to the surfaces of the fittings that come into contact with each other or with the conduit. This lubrication helps prevent corrosion, reduces friction, and makes it easier to install or remove fittings when necessary.

Proper lubrication ensures smooth and effortless movement of the fittings, minimizing the risk of damage during installation or removal.

Replacing Damaged Conduit Fittings

Regular inspections are crucial to identify any signs of damage in conduit fittings. If during the inspection, you find any cracks, breaks, or deformities in the fittings, it is imperative to replace them promptly.

Damaged conduit fittings compromise the integrity of the electrical system, increasing the risk of accidents or failures. It is essential to address any issues as soon as they are detected to prevent further damage or potential hazards.

When replacing damaged conduit fittings, it is important to select fittings that meet the required specifications and standards for compatibility and functionality. Using the wrong type of fitting can lead to improper connections and potential safety hazards.

By following these steps and incorporating regular maintenance into your electrical system’s routine, you can ensure the longevity and optimal performance of your conduit fittings. Remember, a well-maintained electrical system is crucial for the safety and efficiency of any building or facility.

Troubleshooting Common Conduit Fittings Issues

Over time, conduit fittings may experience common issues that require troubleshooting and resolution. Here are a few common issues and ways to address them effectively.

Dealing with Corrosion and Rust

Corrosion and rust can significantly impact the functionality of conduit fittings. If you notice any signs of corrosion, remove the affected fittings and clean them thoroughly using appropriate cleaning agents. Applying an anti-corrosion coating or using fittings made of corrosion-resistant materials can also help prevent future corrosion issues.

Addressing Loose or Damaged Fittings

If you encounter loose or damaged fittings, it is important to tighten or replace them to ensure a secure and reliable connection. Loose fittings can cause electrical arcing and overheating. Gently tighten the fittings to the specified torque, using a suitable tool, without over-tightening and risking damage.

Ensuring Compliance with Electrical Codes

Compliance with electrical codes is essential to ensure the safety and reliability of electrical installations. Here are some key points to consider when ensuring compliance.

Understanding National Electrical Code (NEC) Requirements

The National Electrical Code (NEC) provides the standards and guidelines for safe electrical practices. Familiarize yourself with the NEC requirements and ensure your conduit fittings meet the specifications outlined in the code. Regularly review updates to stay current with any changes or revisions that may impact your electrical system.

Importance of Regular Compliance Checks

Perform regular compliance checks to ensure your conduit fittings, as well as the entire electrical system, are in compliance with the NEC and any other local electrical codes. Regular reviews and inspections can identify any non-compliant fittings or installations, allowing for timely corrective actions to avoid penalties, accidents, or negative impacts on insurance coverage.

Inspecting and maintaining conduit fittings is a critical aspect of ensuring the safety, functionality, and efficiency of electrical systems. By understanding the importance of conduit fittings, following proper inspection and maintenance procedures, and ensuring compliance with electrical codes, you can enhance the longevity and reliability of your electrical installations.